November 12, 2025

New bulk grain stowage type increases efficiency and safety

The International Grain Code is undergoing an update that may impact bulk grain loading operations worldwide. Effective January 1, 2026, the new stowage type of bulk grain increases the efficiency of loading operations, improves the safety of ships, and reduces the uncertainty for ship operators. Shorter loading times at ports result in more efficient vessel operations.

The International Code for the Safe Carriage of Grain in Bulk, commonly referred as the International Grain Code, provides an international standard for the safe carriage of grain in bulk. It defines, for example, the required stowage types for grain in cargo holds, for filled and partly filled compartments. A new optional stowage type will take effect on January 1, 2026, and it concerns partly filled grain holds.

The loading of grain in bulk has been supported by NAPA for decades, being a part of NAPA’s standard offering, following the requirements set by the International Grain Code. NAPA is already supporting the new stowage type in the calculations, including grain shift moment calculations and stability analysis. The upcoming version of loading conditions toolset in NAPA Designer will also support grain loading and stability.

New stowage type of bulk grain

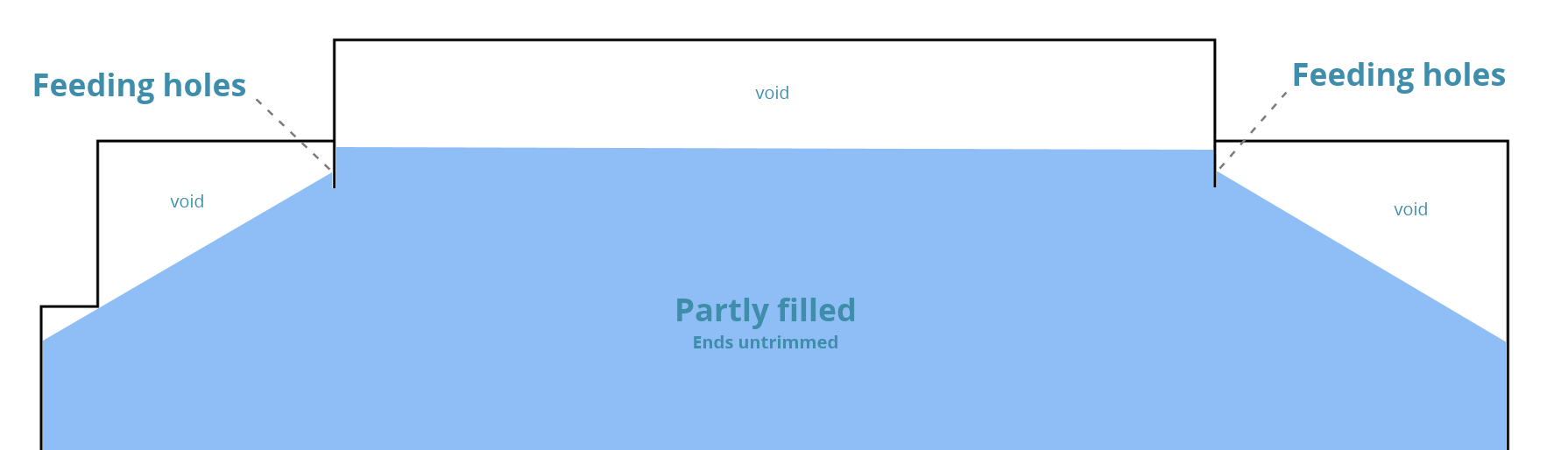

The amendments to the International Grain Code, adopted by the resolution MSC.552(108), will become effective on January 1, 2026. The resolution introduces requirements and guidance for a new optional stowage type of bulk grain cargo, for specially suitable compartments* (cargo holds), which can be partly filled in way of the hatch opening, with ends untrimmed.

What does this mean in practice?

- A hold is not filled to the maximum extent possible in way of the hatch opening.

- The bulk grain is at the level or above with the bottom edge of the hatch end beams.

- The bulk grain level is not trimmed outside the periphery of the hatch opening.

* A cargo space is a specially suitable compartment when it is constructed with at least two vertical or sloping, longitudinal, grain-tight divisions which are coincident with the hatch side girders or are so positioned as to limit the effect of any transverse shift of grain, according to paragraph A2.7 of the International Grain Code.

Increased efficiency and reduced costs

The possibility of using the new stowage type improves loading flexibility by permitting grain to be loaded without the need to trim the ends outside the hatch opening, as long as the cargo surface within the hatch opening is level.

The actual loading operations take a shorter time because the time-consuming trimming of ends is not needed. This naturally also reduces costs for operators and ports.

Operators can maximize the efficiency of bulk grain loading operations by reducing the loading (port) time and utilize their ships more efficiently in operation.

Improved safety

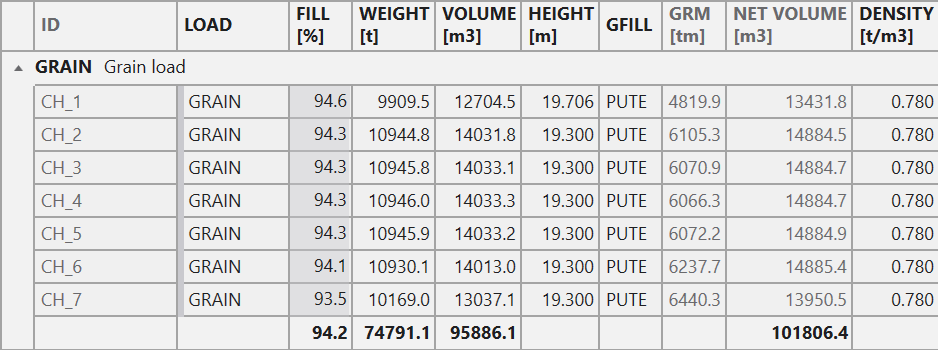

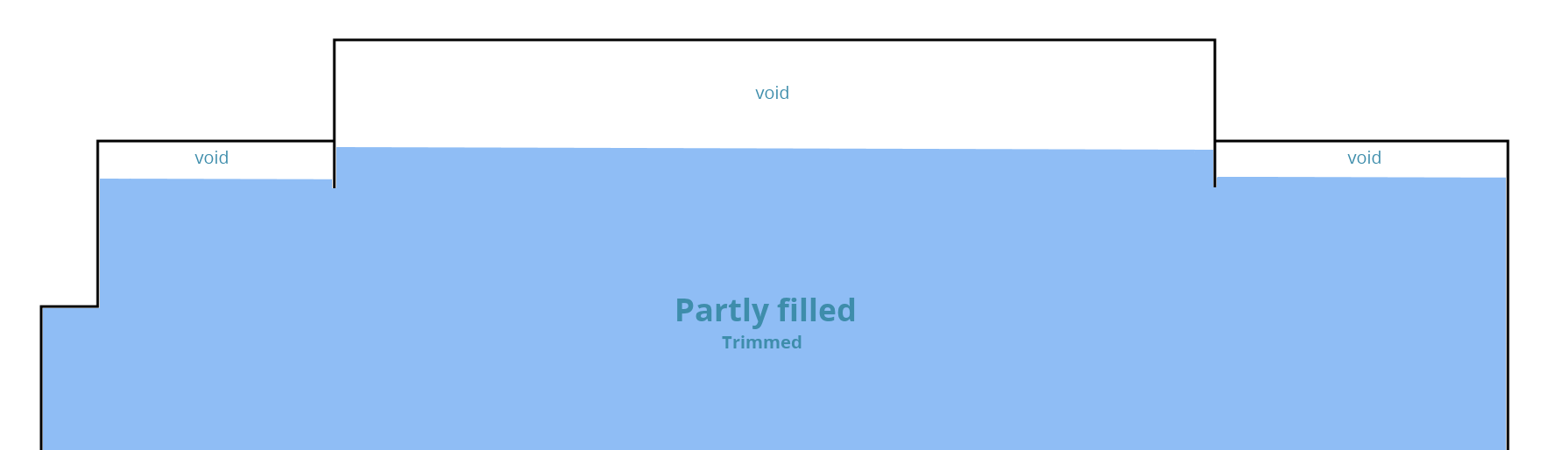

The grain shift moments in the stability documentation for partly filled compartments are calculated by assuming the ends to be trimmed, having smaller voids and therefore smaller shift moments when compared to the untrimmed load levels.

The trimming of ends is a time-consuming and difficult, or even impossible, task to do properly in the actual loading operations, depending on the hold geometry and structures. Therefore, the actual load levels and voids can cause uncertainty for ship operators and even compromise the ship safety because the stability has been verified only for the trimmed load levels, as in the cargo hold section below.

When a ship has compliance with the new stowage type, the stability has also been verified with larger voids and grain shift moments, caused by the untrimmed cargo levels outside the periphery of the hatch opening. This improves the safety of the ship and reduces uncertainty for the ship operator.

Expected effect

The new stowage type will be applicable to new-buildings with keel laid on or after January 1, 2026. However, due to the increased loading efficiency and improved safety, many of the existing bulk carriers could be used more efficiently when supporting the new stowage type. Therefore, many reapprovals are expected to happen for the existing bulk carriers in the near future.

For existing vessels, compliance with the new requirements needs to be demonstrated. The loading and stability manuals, and loading computers, must be updated to reflect the requirements for the new loading conditions. The changes in the documentation and loading computers will need to be approved by the classification societies and flag authorities.

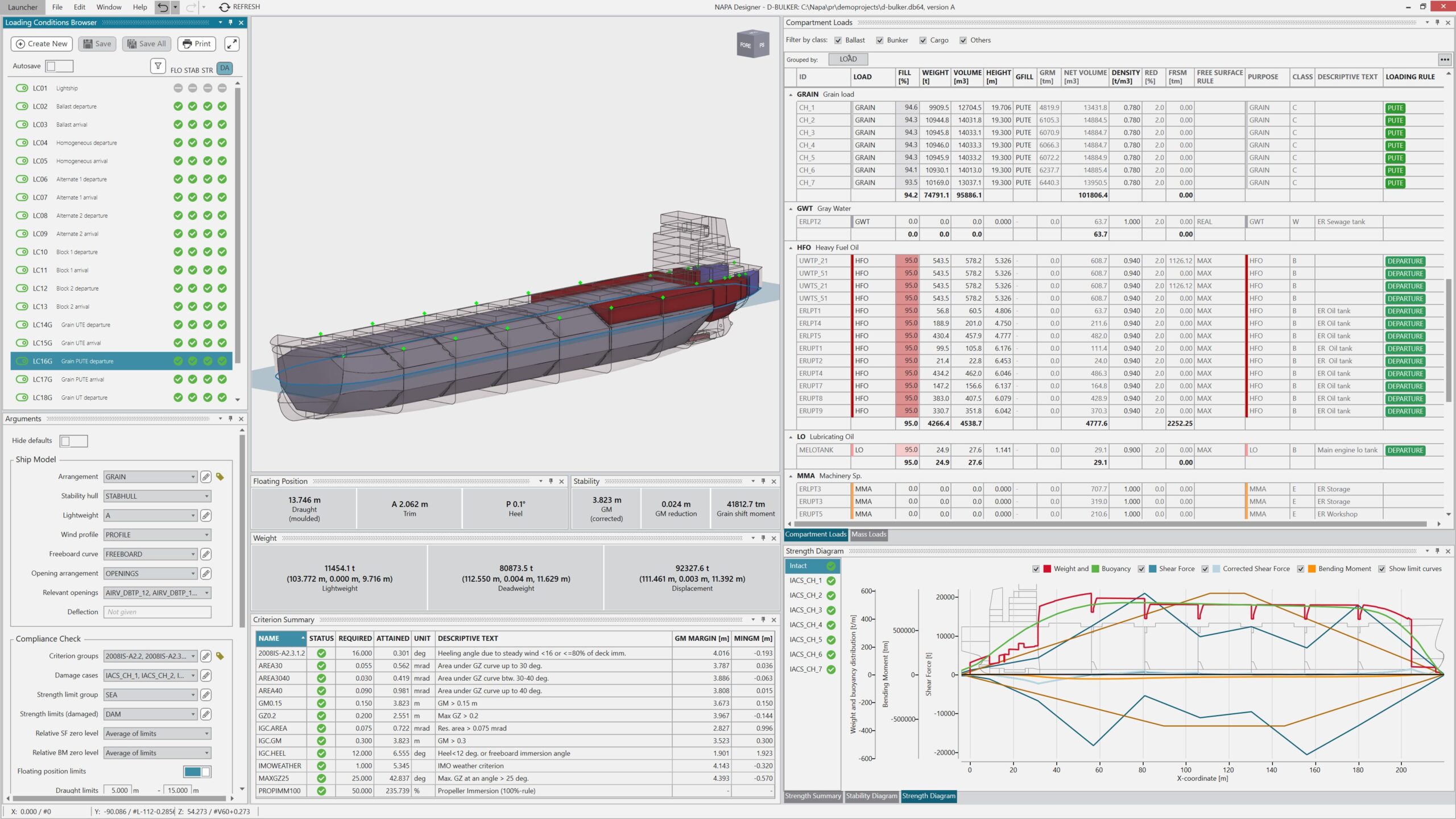

Grain loading in NAPA

NAPA has supported bulk grain loading for decades as part of its standard offering, including grain shift moment calculations and stability analysis in line with the International Grain Code. The new stowage type is already available in NAPA Release 2025.1, enabling loading condition calculations through the classic user interface.

The loading conditions toolset in NAPA Designer has been amended recently to support more and more ship types, and the latest focus has been on the bulk loads. We have introduced user-friendly and intuitive tools for the shear force correction and envelope longitudinal strength calculations. In the upcoming NAPA Release 2025.2, this toolset will be available in NAPA Designer to support the bulk grain loading, with all the required and optional stowage types.

Additionally, the Statutory Compliance Manager application of NAPA, widely used for preparing stability documentation for bulk carriers, will support the new stowage type in the next version, ensuring smooth compliance for both new builds and re-approvals of existing vessels.

Read more here: NAPA Hydrostatics and Stability