Hull Form Design and Hydrodynamics

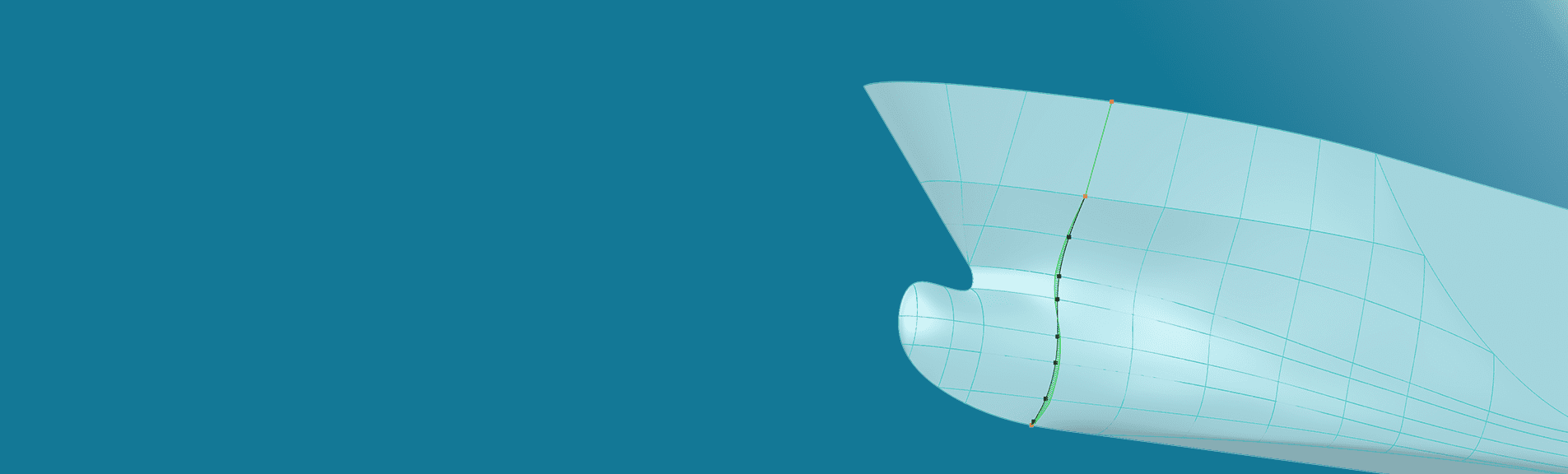

Designing eco-efficient and safe hull forms for real sea conditions

The trusted industry standard for hull form design

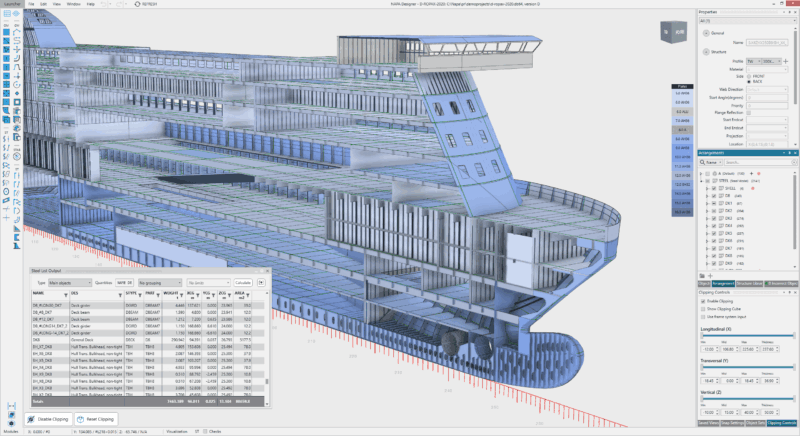

Our advanced hull form and hydrodynamics solutions facilitate efficient ship design processes. With a unique 3D modeling environment and versatile tools for transformations and analysis, NAPA streamlines the design process from concept to production, saving both time and effort. Specifically tailored for ship hull form design, NAPA aids in selecting the required engines and propulsion through integrated powering and propulsion analysis. Additionally, it ensures compliance with necessary regulations related to seakeeping, maneuvering, decarbonization in ship operation, and more.

Benefits

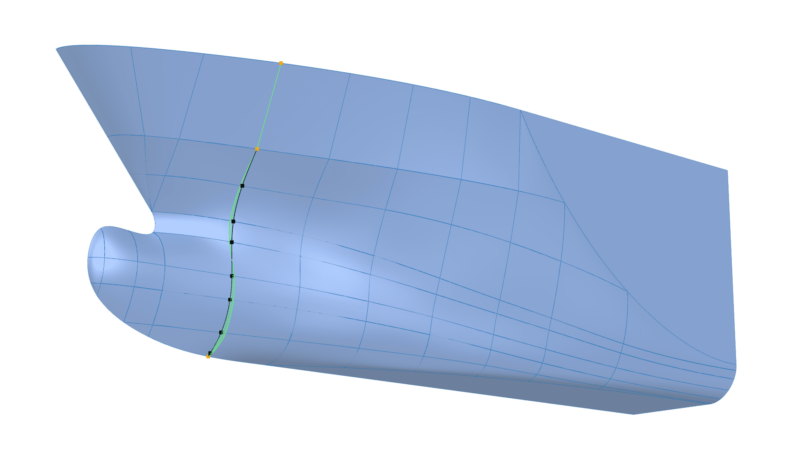

State-of-the-art hull form design

NAPA Designer offers interactive and intuitive 3D-based tools for hull form design. Its unique hull form modeling methodology allows for better control and flexibility in the design process, along with the ability to quickly create design variations through parameterization, global, and local transformations. Integrated stability and hydrodynamic analysis provide immediate feedback.

Optimal designs

NAPA’s hydrodynamic solutions facilitate rapid and precise initial resistance estimation, aiding in defining a ship’s main dimensions, and selecting required engine power and propulsion. The analysis takes into account decarbonization regulations, such as EEDI.

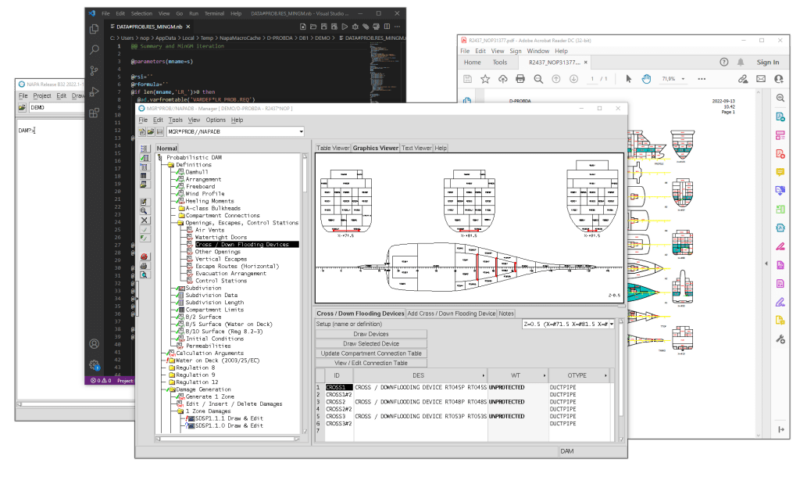

Improved safety with advanced hydrodynamics solutions

Our supplementary solutions for seakeeping and maneuvering guarantee secure and efficient ship operation, all while adhering to crucial regulations.

More insights

Software

Questions or Demo?

Get in touch or Book a demo

Please complete the form for answers to your questions and an in-depth introduction to our offerings.

To book a live demo with a NAPA representative, simply check the demo reservation box in the form.

By submitting the form, I consent my information to be used according to NAPA’s privacy policy.