June 26, 2025

A digital toolkit to shape the future of ship design: NAPA User Meeting 2025

Bright minds of the ship design community gathered once again for the NAPA User Meeting 2025 in Helsinki, Finland. United by one common aim: to tackle growing ship design complexities, naval architects, structure engineers and hydrodynamists came together for a week of knowledge sharing and learning to unlock opportunities for greater efficiency, innovation and collaboration.

Ship design has entered a new era defined by both opportunity and complexity. The global shipbuilding orderbook reached a 17-year high in 2024, with shipyard output also increasing by 13%. Demand is looking strong, driven by diverse needs ranging from greater sustainability to high-value specialty vessels and innovative cruise ships that emphasize unique guest experiences.

Wider industry trends also cannot be overlooked and include growing government investments in shipyards, an increase in defense spending and interest in Arctic operations. In responding to these challenges, shipbuilding is grappling with labor and skills shortages, the pressures of digital and decarbonization transformations and tighter timelines, all while balancing the demands of an ‘engineer-to-order’ approach in shipbuilding. In this fast-evolving environment, flexibility won’t just be helpful- it’s essential.

With more ships, regulations, and complexities, there’s also more opportunity to rethink how we design and operate vessels. At the NAPA User Meeting 2025, it was clear that digital innovation isn’t just a buzzword- it’s already reshaping how we work. Whether it was a digital continuity process using integrated 3D information or managing engineering workflows with node networks, these five takeaways capture just a snapshot of the ideas we explored together.

1. Digital continuity from concept to detail design and production using 3D models

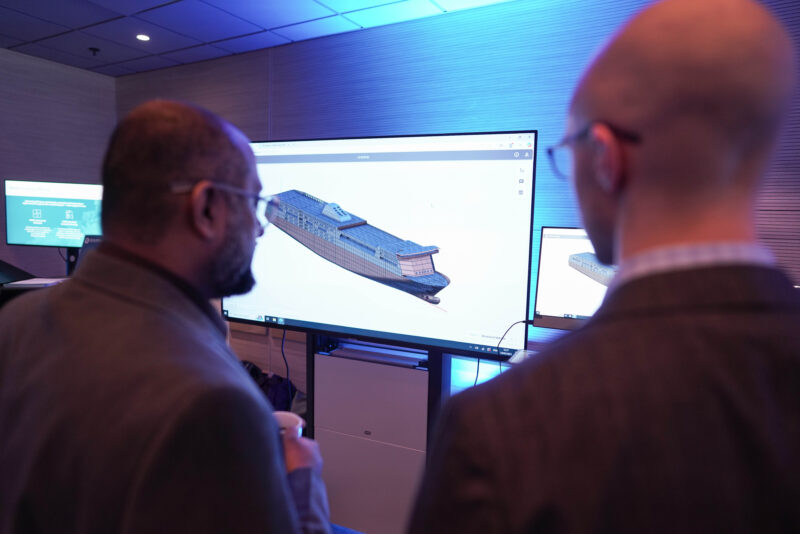

Designing a vessel is one thing, but building it efficiently is another. That’s where disruption and innovation in ship design are key. At the User Meeting, Takayoshi Masui, Director, Business Development (Structure Design) at NAPA, demonstrated how the NAPA 3D model can be utilized beyond the basic design stage and can be used to support smart detail design, as well as data reusability in downstream processes.

Putting this into practice, Claire Baccard, Hull Technical Department Manager at Chantiers de l’Atlantique shared how the shipyard’s hull technical department is making this digital continuity a reality. Following Takayoshi’s presentation, Claire discussed how her team has been extending the 3D workflow of hull structure design with NAPA, from basic to detail design, to enable a high level of data reusability in the production design phase with Smart3D. This “best-of-breed” approach supports the rapid modeling of structures using a shipbuilding-specific toolset to accommodate efficient design modification and more design iteration cycles.

NAPA is supporting the project not just as a software provider, but as a true collaborator, co-developing workflows and offering technical insight into hull design to bring a shared vision to life. The project is a real step forward towards creating a digital shipyard and contributing to high-quality results, efficient processes, and cost savings.

2. Visualizing engineering workflows with Node Networks in NAPA Engineer

Modern ship design is increasingly complex with new regulations, calculation methods and innovation- but it doesn’t have to be overwhelming. Jan Furustam, Director of Business Development, and Thijs Muller, Marine Advisor at NAPA Design Solutions, introduced the Node Network approach in NAPA Engineer, an integrated naval architecture platform. It uses a low-code, visual method to simplify complex design and data workflows, showing clear dependency mapping between disciplines.

By organizing functions into modular nodes, naval architects can quickly and efficiently test changes, rerun calculations, and explore alternatives- all within one environment. Putting this to the test, Jan and Thijs presented a case study using NAPA Engineer and the node network to assess the probabilistic damage stability of a vessel. They showed how this method enables quick stability checks, flexible design, and a more holistic, visual view of multi-disciplinary ship design challenges.

The alpha version of NAPA Engineer is available now.

3. A powerful Swiss army knife built for customization

In his presentation, Radovan Gasparovic, M.Eng., Head of Stability & Weight at Ulstein Design & Solutions AS, referred to NAPA as a “Swiss Army Knife” for ship design- and for good reason. With a tool for any calculation, analysis, or simulation, NAPA is helping Ulstein tackle complex design challenges and shift industry requirements.

Building on a long relationship with NAPA, Ulstein has tailored NAPA for a wide range of activities, from an advanced approach for analyzing cross flooding calculation results to producing polar class drawings, automating AutoCAD exports and stability booklet generation. NAPA’s flexibility allows Ulstein to meet complex regulatory demands without resorting to one-size-fits-all solutions.

The presentation was inspiring and demonstrated Ulstein’s deep commitment to shipbuilding excellence. As Radovan put it, “the only limits are our ideas, not NAPA.” With proper training, curiosity, and a bit of experimentation, teams can unlock massive time savings and scale efficiencies.

4. Bridging the ship design value chain from design to class approval with 3D models

We continue to see the power of 3D Model-Based Approval (3DMBA) in action. In a joint presentation, Sami Gusani, Development Engineer, Shipbuilding Design at Meyer Turku; Ole Christian Astrup, Senior Principal Specialist, Calculation Tools, DNV- Maritime; and Myeong-Jo Son, Senior Software Developer at NAPA Design Solutions explained how they are working with NAPA to close the feedback loop between shipyard and class, using a shared 3D model as the single source of truth.

They explained how, with NAPA Viewer, teams across disciplines and organizations can review the 3D model, assign comments, and track revisions in one secure, web-based platform. This streamlined approach is cutting down errors, speeding up approvals, and removing the need for time-consuming 2D-to-3D conversions. With real-time input from all stakeholders, 3DMBA is transforming the ship design and classification approval process into a faster and more connected one.

5. Innovation through collaboration

The NAPA User Meeting has always been a unique opportunity for naval architects and maritime experts to find a chance of real collaboration, knowledge-sharing and discussing new solutions. This year was no different. Whether it was through open Q&As, live demos, the NAPA Showroom or hands-on workshops, everyone came ready to share insights and collaborate.

As the NAPA user community gets bigger and more connected than ever, the benefits of these discussions are clear; it’s in allowing peers to share how they are tackling today’s design challenges, explore the potential for joint projects and discuss what the future of ship design can look like. From fresh voices to industry veterans, the User Meeting provided a space for open collaboration that goes beyond competitive boundaries and empowers users to challenge the status quo. There’s even greater value in doing so face-to-face, building relations that carry beyond the event itself.

Looking ahead to the future of ship design

If there was a single takeaway from the week, it’s this: innovation happens when we work together and this collaboration isn’t just a ‘nice-to-have’, it’s essential.

As ship design transforms under market, customer and regulatory pressures, the industry doesn’t need a one-size-fits-all tool; it needs a powerful toolbox that is intuitive and user-friendly, which naval architects and engineers can use to innovate and test the bounds of their creativity. This can only happen if we’re all actively sharing knowledge, insights and collaborating to build smarter solutions and ways of working.

At NAPA, we see ourselves as more than a software provider; we’re here to co-create the next generation of design tools with and for naval architects. Only by working together can we shape a smarter, safer and greener future for ship design and shipping.