August 19, 2025

Naval Group: Designing safe and stable navy vessels

NAPA and Naval Group’s Weight-Stability Service team collaborate to simplify designing and operating navy vessels. Unlike commercial vessels, stability analysis and calculations for naval vessels demands a holistic, collaborative approach. With constantly evolving class, civil and naval rules, designing naval ships requires a blend of technical proficiency, regulatory know-how and advanced software. Using a single 3D model throughout the vessel’s lifecycle, NAPA ensures stability management is consistent, engineering calculations are done accurately, and that teams from other design disciplines can also access stability information seamlessly.

Naval vessels are among the most complex engineering feats in the maritime industry. Their compact size, high structural strength requirements, and varied missions demand precision in design and engineering, all while complying with rigorous classification rules and safety standards.

France headquartered Naval Group, a global leader in naval defense, has successfully navigated these challenges by combining operation and design data, using advanced digital tools with NAPA by its side. From the mass estimate of the vessel to the construction process and during operations, Naval Group’s 13-strong Weight-Stability Service team use NAPA technology to conduct stability analysis to not only ensure the ship meets the criteria imposed by regulations but also that it is operating safely.

Background: What the navy needs

Naval vessels must meet the diverse needs of navies, which can range from mine clearing and submarine warfare to troop transport and coastal protection. These vessels vary in design to respond to their missions, from corvettes and frigates to aircraft carriers. They are also highly complex. Aircraft carriers, for example, will demand a different approach to loading and stability analysis than a standard tanker, with the need to ballast the vessel or allow smaller vessels to go inside.

While the fundamental design of naval ships may not have drastically changed over the years, the process of validating those designs has become more detailed. In addition to changing civil and naval rules, classification society requirements change regularly to ensure these vessels adhere to rigorous safety standards. One key challenge at the heart of this change is managing vessel stability, from the design through to the operational stage. This is easier said than done: there are multiple stakeholders, evolving civil, naval and classification rules to follow, and a myriad of operational considerations.

Moreover, due to the highly sensitive nature of naval operations, all stakeholders involved – from ship designers to technology providers, classification societies and end-users – need to make sure this data is secure. Thus, having all data on a single platform, from the early design stage to type approval and operations, helps ensure everything remains within a secure, closed ecosystem.

With a partnership spanning almost two decades, Naval Group’s Weight-Stability Service team shares how it has been working with NAPA to conduct advanced stability calculations and analysis, while enabling collaboration, transparency, efficiency and safety.

Enabling seamless communication with multiple stakeholders using NAPA 3D models

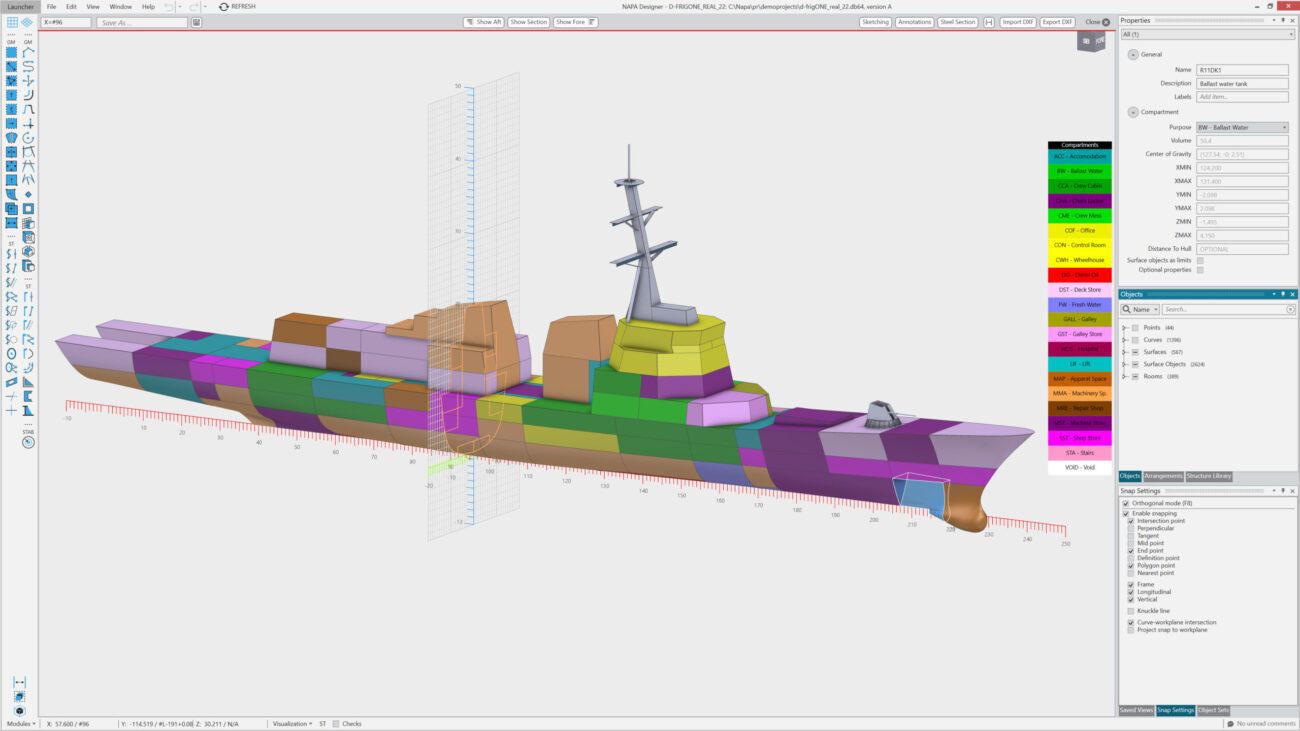

Stability is a critical part of a vessel’s operability and Naval Group has been able to deploy a single NAPA 3D model for stability calculations and analysis across a vessel’s lifecycle, from the basic design stage to midlife refits, ensuring all engineering calculations are done on the same model.

Stability analysis starts by building the vessel’s 3D model with the mass estimate, accounting for basic vessel data such as dimensions and arrangements, which also informs the ship’s displacement and center of gravity.

As the project progresses, so does the 3D model to include more detail on the vessel, around the main bulkhead, for example, helping conduct intact and damaged stability studies. These insights have allowed naval engineers to understand the associated limits for height and weight distribution, for example, which is particularly important given the space constraints of naval vessels and the need for auxiliary equipment.

By using the same 3D model throughout the vessel’s lifecycle, the Weight-Stability Service team can ensure data is consistent, engineering calculations are done accurately, and that teams from other design disciplines can also access this information seamlessly. This has allowed Naval Group to comply with evolving rules, define tailored criteria in line with the latest requirements and client needs, and streamline data sharing. The team can do all this, and more, without overhauling workflows or causing discrepancies.

Quickly adapting designs to meet evolving rules with swift, reliable customer support

Classification, civil and naval rules, as well as the vessel’s design detail requirements, are constantly evolving during the design process. Which means designing naval ships requires the right blend of technical proficiency, regulatory know-how and advanced software. This isn’t something Naval Group has to chart alone.

NAPA works closely with Naval Group to develop proprietary macros within the platform to align with these dynamic and specific criteria. With this tailored support, the Weight-Stability Service team is able to better understand what they can solve with NAPA and, therefore, use it to its full potential. As William, Naval Architect, Naval Group, describes it, “we want NAPA to tell us what we can do and how to use NAPA solutions for new tasks. Most of the time, NAPA can solve the things that we’d like to solve… we return with a lot of answers.”

With ever-changing rules and unique requirements, ship design for naval vessels is no easy feat and demands technical expertise, regulatory knowledge, and advanced software. By utilizing a unified 3D model throughout a vessel’s lifecycle, NAPA is supporting Naval Group in not only integrating ship design and engineering disciplines for better informed decision making, but also ensuring teams at the operational stage can access this model and its data to optimize operations and enhance vessel safety.