January 29, 2026

Extending OCX: Unlocking new horizons in ship design and safety

OCX is redefining the digital backbone of shipbuilding — and its potential extends far beyond just 3D Model-Based Approval. As a core member of the OCX consortium, NAPA is advancing model-based workflows that integrate structural approval, FEM data, and stability analysis, enabling smarter, safer, and more connected ship design.

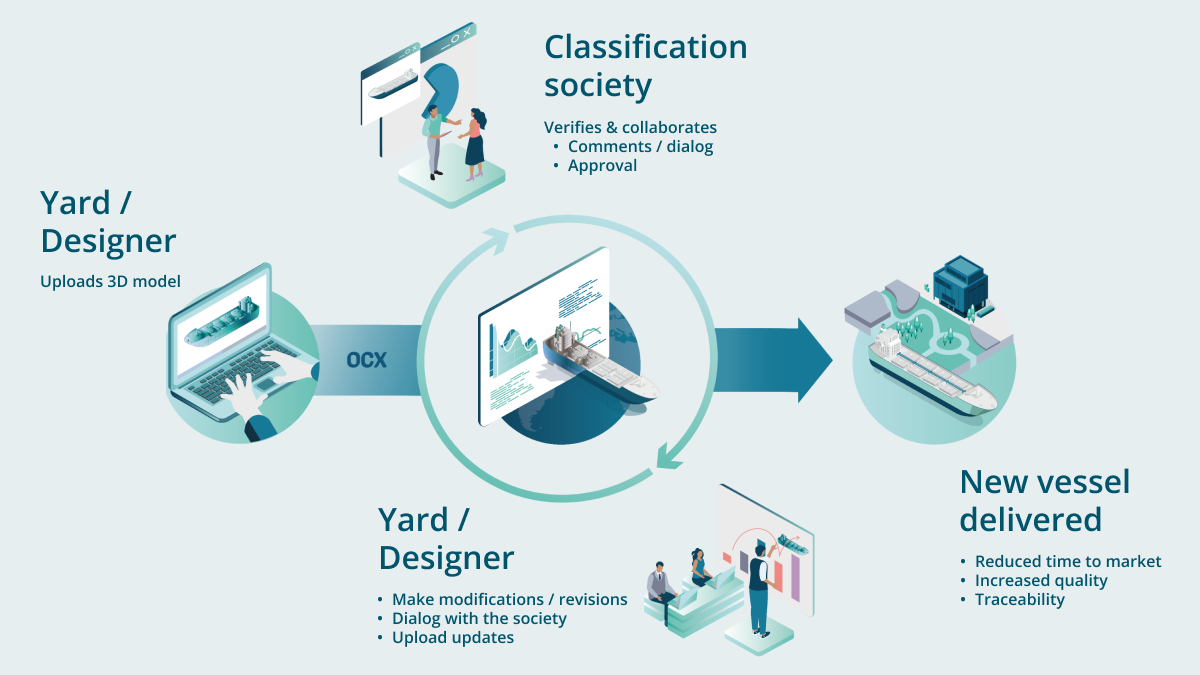

The OCX Consortium and the Interoperability Forum have been working on developing the Open Class 3D Exchange Format (3D OCX) since 2021. As an extension of the APPROVED project, the primary focus of the development is on the data format to support a 3D model-based classification approval process. NAPA joined the consortium as a full member from the beginning and actively participates in developing the standard and its implementation in software capability. The first projects are already using the 3D-based approval process, and the industry is starting to turn away from a traditional 2D drawing-based way of working towards 3D Model-Based Approval.

At the heart of this evolution is the Open Classification 3D Exchange (OCX) format, a standardized method for exchanging 3D ship structural models, originally developed to streamline classification approval. But what if OCX could do more? Recent research and industry collaboration suggest that OCX’s potential extends far beyond its initial scope, offering new efficiencies and safety enhancements across the entire ship lifecycle.

From structural approval to multidisciplinary integration

OCX was designed to replace manual verification tasks and 2D drawings in the structural plan approval process. As model-based workflows matured, stakeholders began to explore OCX’s value in cross-disciplinary ship design. Applications now include:

- CAD-to-CAD model transfer

- Finite Element Modeling (FEM) generation

- Verification of regulatory requirements

- Automated comment exchange between classification societies and design tools

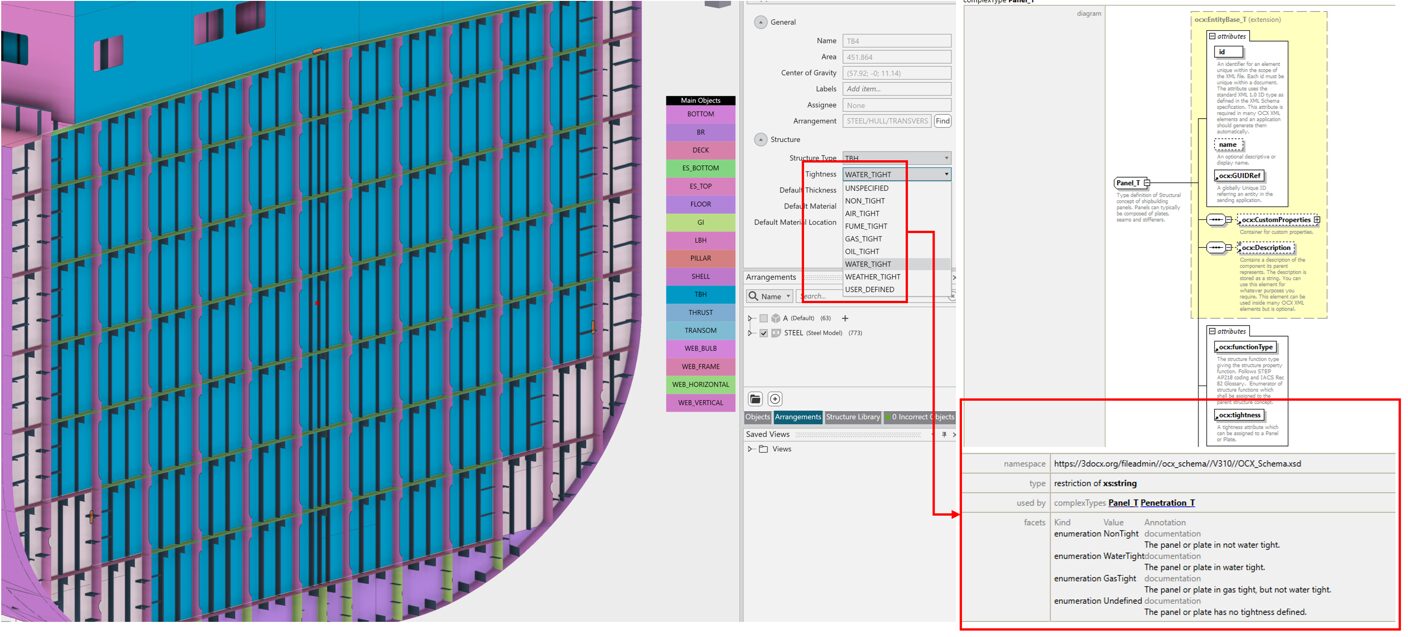

A key innovation is the use of custom properties, which allows flexible, key-value metadata to be attached to any element in the OCX schema. This enables specialized business scenarios, such as corrosion deduction thickness or tightness attributes, without altering the core schema.

Practical extensions: FEM, data sharing and data output

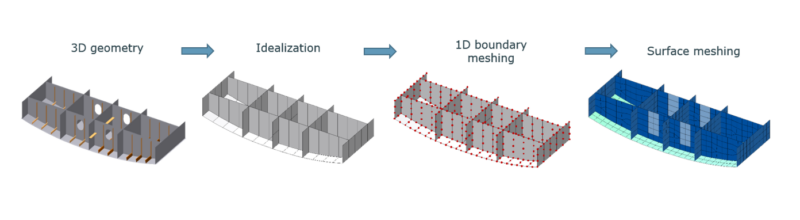

FEM Model Integration

OCX can now serve as a single source for FEM data, supporting various solver formats (Nastran, ANSYS, DNV Sesam, Abaqus). By extending OCX with custom properties for nodes, shell elements, and line elements, FEM models can be embedded directly within the structural hierarchy. This approach enables:

- Natural grouping of FEM elements by structural object or compartment

- Automated import of FEM models into tools like NAPA Designer

- Streamlined workflows for load definition and corrosion analysis

Information and data sharing

Shipbuilding involves diverse stakeholders and specialized applications. OCX’s standardized structure supports integration with Product Lifecycle Management (PLM) systems and facilitates the digital thread. By incorporating industry ontologies, for example the SFI Coding and Classification System, OCX can help structure procurement, cost estimation, and lifecycle data management. This development also enables knowledge graphs and SLM/LLM applications for industrial data locked in 3D models.

Data output and material lists

Accurate estimation and control of steel weight and material lists are critical. OCX’s flexible labeling and grouping features allow designers to match shipyard customs and reference documentation, while also supporting detailed breakdowns for procurement and error checking.

OCX for stability: A new era in safety

Perhaps the most transformative extension is the use of OCX for stability analysis and approval. By embedding watertight integrity data, such as subdivision bulkheads, doors, and closures, directly in the 3D model, OCX enables:

- Automated verification of watertight boundaries and openings

- Consistent data flow from design to approval and onboard monitoring

- Early detection of subdivision issues and compliance with SOLAS, MARPOL, and IBC Code requirements

Integration with NAPA Stability enables direct simulation of flooding scenarios, supporting both deterministic and probabilistic damage-stability assessments. This unified approach reduces manual work, minimizes errors, and paves the way for digital twins that enhance operational safety and decision support.

Conclusion: Toward a digital backbone for shipbuilding

Extending OCX beyond 3D structural approval unlocks significant benefits:

- Automation of regulatory compliance and stability analysis

- Streamlined data sharing across design, approval, production and operations

- Enhanced safety through real-time monitoring and vulnerability assessment

As the industry moves toward a single source of truth for ship data, OCX is positioned to become a key element in the digital backbone of ship design, approval, and operation—enabling earlier feedback, fewer late-stage changes, and a safer, more efficient future for maritime engineering.