September 8, 2025

NAPA – Ulstein’s Swiss army knife for ship design

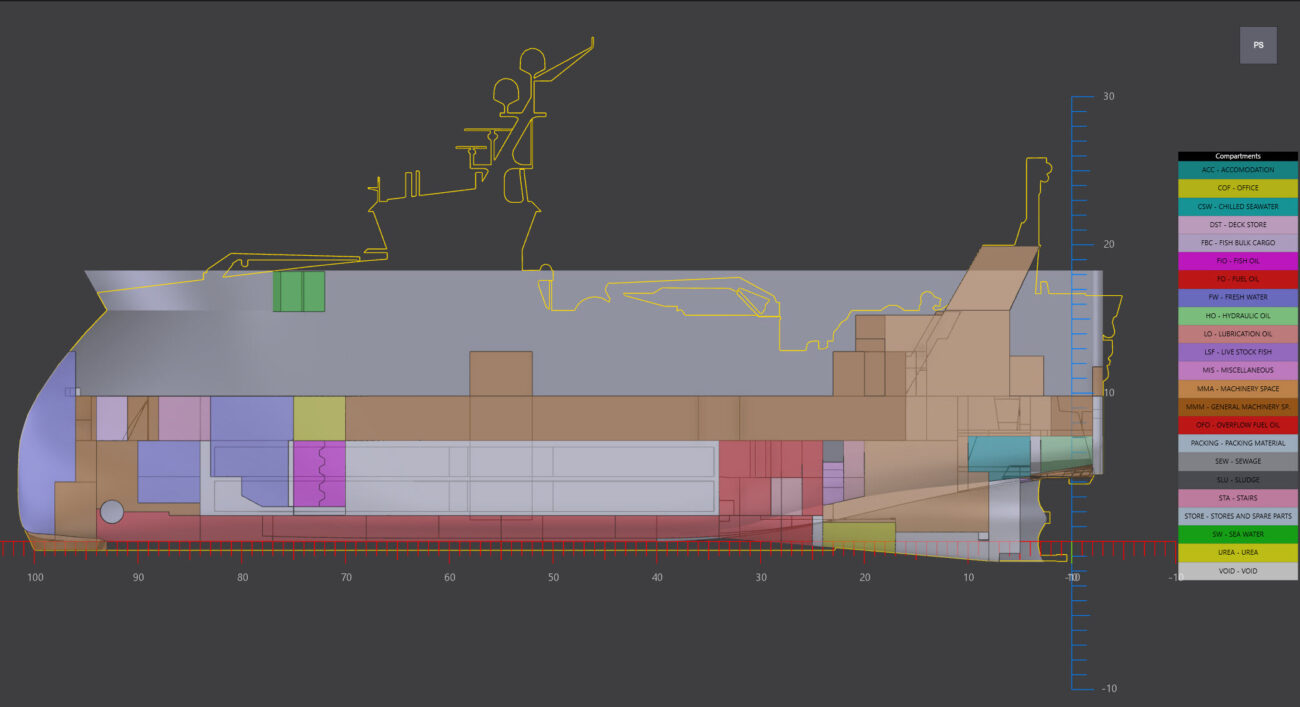

A Swiss army knife is valued for its versatility as an adaptable tool ready for almost any challenge. It’s a comparison that Radovan Gasparovic, Head of Stability and Weight at Ulstein Design & Solutions AS, draws when describing NAPA as the “Swiss army knife” of ship design. With rising regulatory demands, increasingly complex vessel configurations and rapid digital innovation, ship designers need equally versatile tools to stay ahead and solve complex problems quickly, without compromising on quality or precision.

Ulstein, based in Norway and globally recognized for its smart, sustainable vessels, including X-BOW®, a distinctive inverted bow design, has long embraced this challenge. From early offshore projects to exploring today’s advanced passenger ships, Ulstein has relied on NAPA for more than 30 years. With a toolset that supports everything from geometry design and hydrodynamics to damage stability, NAPA enables Ulstein to deliver innovation at pace in a high-stakes, ever-evolving industry.

One Swiss army knife, endless possibilities: How NAPA adapts to every design challenge

Efficiency, accuracy, and agility are essential for ship designers, but with multiple timelines and disciplines at play, optimizing processes isn’t always easy.

However, as Radovan emphasizes, ship design improvements don’t need a complete process overhaul; even small changes, with better integrations or automations, can create tangible efficiencies that, when multiplied over time, generate even greater savings. On his team of five, with experts focusing on stability calculations, as well as on hull modelling and hydrodynamics, these time and resource savings are significant.

Ulstein has customized NAPA for a wide range of activities, from automating AutoCAD exports to creating macros for polar class ships. Unlike rigid tools, NAPA gives them the freedom to build and test custom solutions, saving hundreds of manual working hours.

Radovan explains how existing NAPA functionalities have been helping his team build a custom toolset to define cross-flooding arrangements with automatically calculated friction coefficients. His team will be able to quickly and easily evaluate the final friction coefficient values for each cross-flooding arrangement of a project, leading to accurate cross-flooding times in the damage stability calculation. By customizing NAPA’s tools and building a solution to meet specific requirements, Radovan emphasizes how these time-investments are not only scalable but also help build transparency.

It is, therefore, no wonder that Radovan sees NAPA as a “Swiss army knife” with its ability to adapt, provide modular capabilities, and offer macro scripting options that let users shape the software to their exact needs.

The magic of customizing digital tools to bring ship design ideas to life

The ship design and ship building landscape has changed immensely and will continue to transform with the demands of complex regulations, rules and customer requirements. With so many ways to tackle these challenges, real technical expertise is invaluable in tailoring tools to meet specific needs, tapping into the potential of NAPA as a toolbox.

As Radovan puts it, “the only limits are our ideas, not NAPA” and with the right training, as well as a bit of curiosity and appetite for experimentation, ship design teams can unlock massive time savings and scale efficiencies. This customization can provide a competitive advantage for ship designers at a time when there is fierce competition to maximize shipyard productivity and design efficiency.

There is, however, a balance to be struck between customization and using existing solutions.

“There are definitely tools which we use because they’re just so good and we are not missing anything with it.” Radovan highlights.

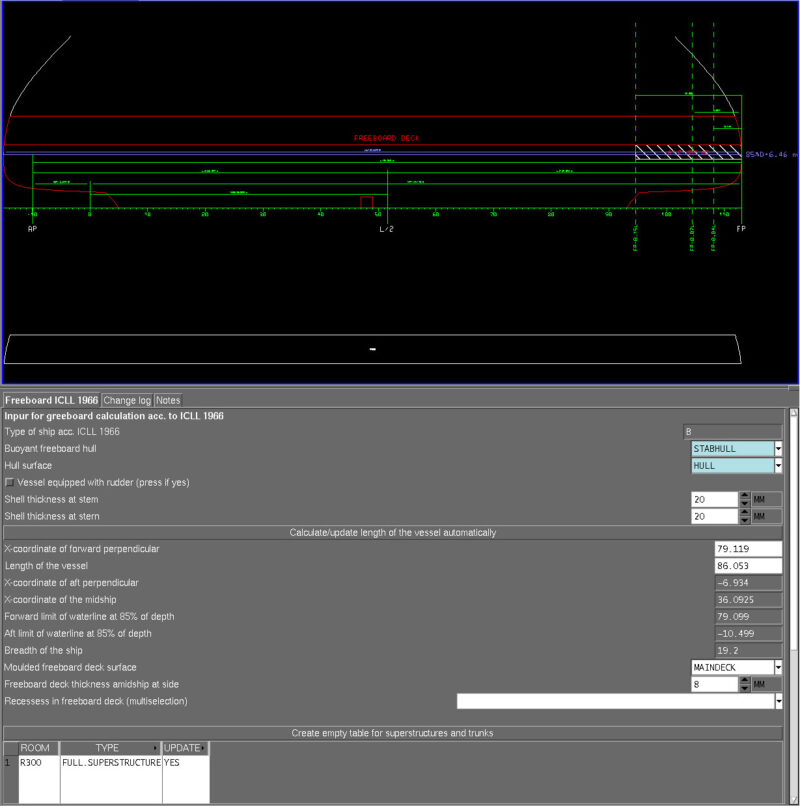

Keeping up with evolving stability rules and requirements

Stability rules and regulations have changed significantly in recent years. Intact stability is no longer the only area of focus, and IMO regulations are increasingly looking at probabilistic damage stability as well. Designing vessels to be safe and stable, therefore, requires comprehensive calculations and significant computational time.

These calculations are central to Ulstein’s everyday work and require both speed and precision. “Probably the most important tool for us is the probabilistic damage stability application of NAPA. It’s used daily and is a great tool. We haven’t developed our tool for it, so we see it as a very important part of our toolbox.” said Radovan.

NAPA is always updated to meet new requirements from the IMO, flag states and other regulatory bodies, giving Ulstein the confidence that their tools will support compliance without slowing them down. Taking this further, Radovan points out that NAPA can “sometimes actually be a little bit ahead of the rules and regulations,” which is extremely important not only for Ulstein but for the safety of the industry.

But even a Swiss army knife benefits from a bit of sharpening. Through open collaboration and active knowledge sharing with NAPA, topics like progressive flooding and design data exchange via 3D models aren’t just explored – they’re co-developed, driving innovation that benefits the wider maritime industry.

Sailing towards a greener, smarter future

Every aspect of ship design is changing and there is plenty of work to be done. From enabling closer collaboration between classification societies and shipyards to incorporating new alternative fuel and energy efficiency technologies onboard vessels, the future of ship design is full of possibilities.

In this climate, the relationship between Ulstein and NAPA is more than just transactional – it’s an evolving partnership that has grown with the pace and complexity of the maritime industry. Underpinned by a shared commitment to innovation, creative thinking and collaboration, both teams are well-positioned to tackle the ship design challenges of tomorrow with speed, agility, and confidence.

With this approach, in Radovan’s words, the “sky is the limit.”