January 16, 2024

How to model your alternative fuels future

Want to know what your fleet’s alternative fuels future will look like? You’re not alone. As new energy sources make their entry on global fleets, shipping is craving certainty. But there is no need for fortune-telling – instead, simulation tools can reveal what to expect in terms of new ship designs, operations, and costs, for every fleet. Ready to try? Here’s how it works.

Shipping’s appetite for alternative fuels and innovative ship designs is undeniable. While vessels that can operate on alternative fuels today still represent a tiny proportion of the world’s fleet – around 6.52% in gross tonnage – their number is set to rise sharply. Around half of the global orderbook in 2023 was for vessels that are set to run on alternative fuels or power systems, including methanol, LPG, LNG or batteries – compared to a third the previous year, according to analysis by DNV.

This increased demand for alternative fuels is in large part driven by a simple calculation: having an energy efficient fleet pays off commercially. We already see that modern energy-efficient vessels tend to achieve better chartering rates than their older counterparts, with premiums reaching several thousands of dollars per day, and even more for certain vessel types.

The business case will continue to grow not only for fuel efficiency, but also for substantial greenhouse gas emissions reductions as an aim in itself. The recent expansion of the European Union Emissions Trading System (EU ETS) to shipping means that ships are now required to pay for their CO2 emissions, putting a direct price on carbon. This adds to the IMO’s Carbon Intensity Indicator (CII) regulation, which aims to tie a ship’s competitiveness and business prospects to its operational efficiency. Going forward, poorly rated ships may struggle to secure business and financing, while top-rated vessels are likely to have a competitive advantage.

Balancing risk and opportunity

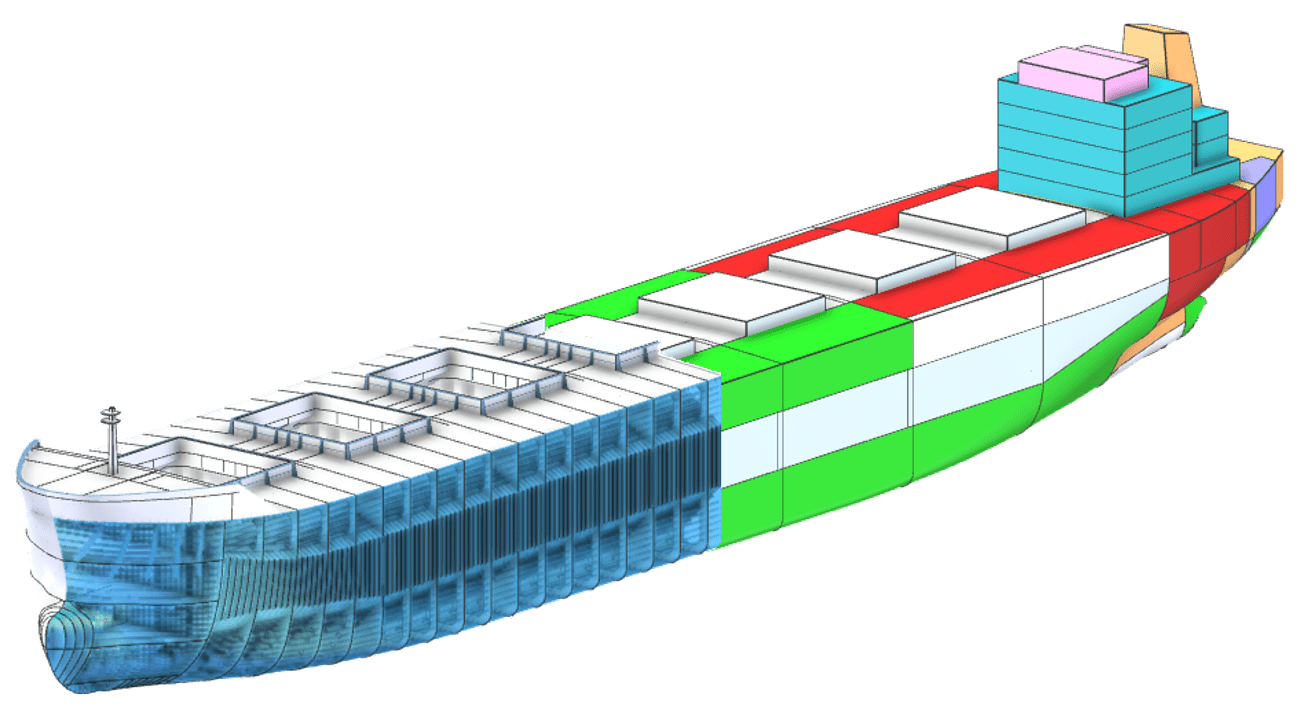

As a result, there are huge potential gains for shipowners who pioneer the use of alternative fuels. But this strategy isn’t without risk. Transitioning to new fuels has massive implications for a ship’s safety, stability, and configuration, while requiring the integration of new storage tanks which can reduce cargo capacity and therefore impact commercial profitability. Getting it right is vital, but how?

Part of the answer lies in thinking creatively about how we use and combine tools that are already at our disposal. Here, much insight can be gained by using operational simulation capabilities together with 3D tools in ship design.

How operational data brings new insights for ship design

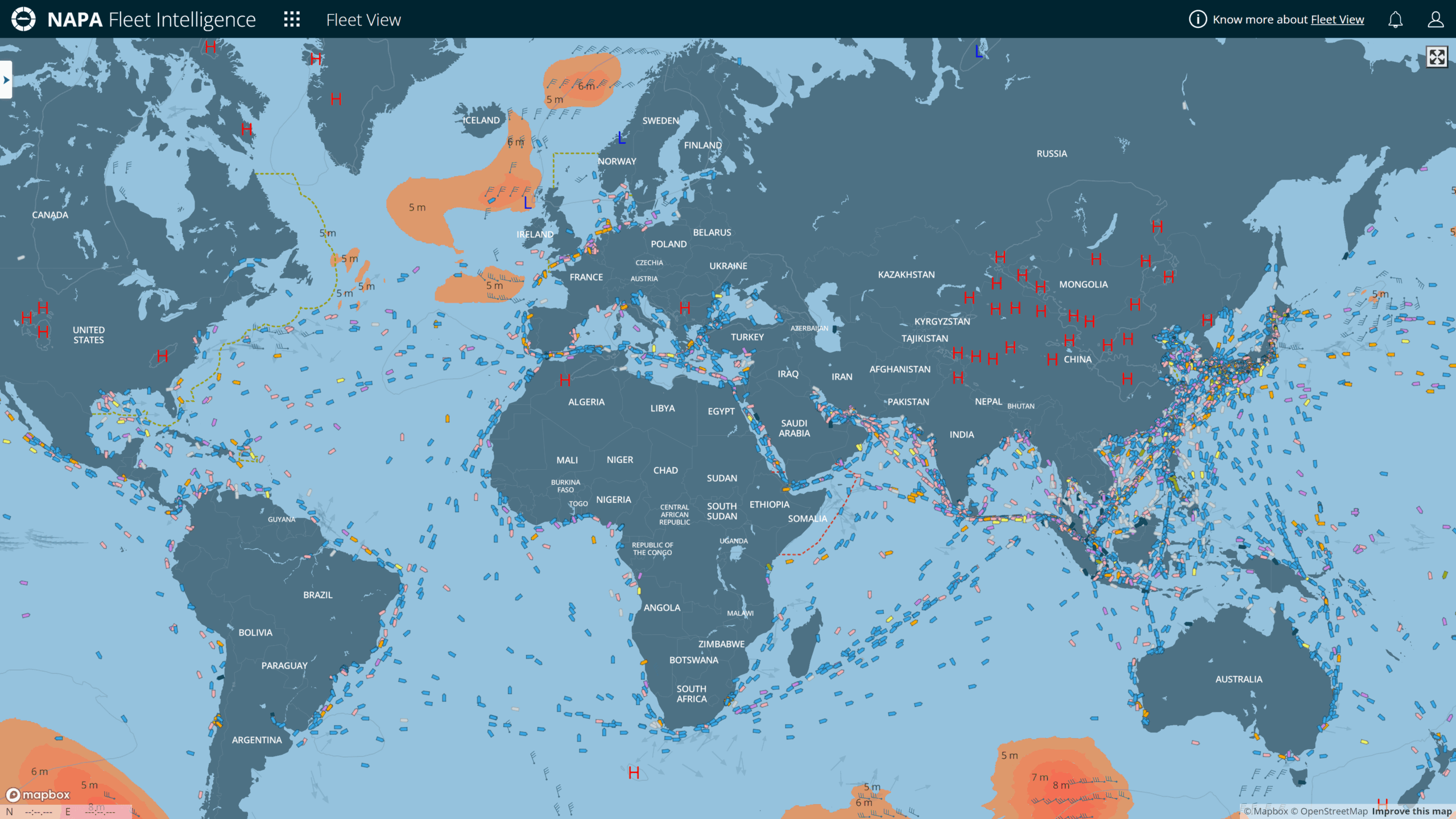

This is already a reality today – naval architects and engineers can use operational simulation models to get a detailed picture of the range of weather and sea conditions on the routes where the future ship will be operated.

This analysis is powered by historical data on wind speed and direction, wave height and swell, and current speeds and directions. From there, direct strength analysis and load assessment can be conducted using 3D models created in NAPA Designer, helping simulate the future stresses on the hull in a realistic manner and adjust designs accordingly.

This data-driven picture of weather and sea conditions data can also be used to simulate the real-life emissions reductions that wind propulsion systems are likely to achieve for the specific ship, giving shipowners more certainty before investing in those systems.

As we enter a multi-fuel era, operational simulation can also deliver precious insights into the range of speeds at which the future ship will be operated as well as its future fuel consumption. This helps determine the optimal engine power required, but also the size of the fuel tanks that will be needed for the vessel. Given that future fuels such as ammonia, hydrogen and methanol are less energy-dense than their fossil fuel equivalent, getting this assessment right is critical as it can minimize the loss of cargo space.

Comparing options to make the best decisions

The magic is fully unlocked when we combine insights from operational simulations with digital twins to test different design variations and model how they would behave in real life. For example, 3D models can be used to compare different configurations for alternative-fueled vessels and calculate the impact on the vessel’s future performance, fuel consumption, GHG emissions, stability parameters and hydrodynamic profile.

This capacity to test different shapes and profiles easily helps naval architects and engineers evaluate where exactly new systems such as batteries or additional tanks should be installed on a ship, accounting not only for the total volumes needed but also for where they need to be installed to ensure safety.

These simulations can be done from the early concept design stages, and the results increase in accuracy as the design progresses and more details are confirmed. In tangible terms, teams will be able to trial different options throughout the process to support the multiple decisions that have to be made as the design progresses from the initial phases through to structural and more detailed phases. In other words, simulation tools help remove the “guess work” and back decisions with data and evidence.

Estimating emissions and costs – the multi-million-dollar question

For shipowners, this matters because they gain a better understanding, from the early design stages, of what different fuel options, such as LNG or methanol, would look like in real life, as well as their implications for cargo capacity and predicted fuel consumption. As the ship design takes shape, simulation tools can model its future levels of GHG emissions, and how this will impact compliance with environmental regulations.

Ultimately, the aim would be to use those estimated emissions levels to predict the combined costs related to buying the fuel itself and emissions allowances for different fuel options. Simulations could show when a design would become cost-competitive under EU ETS, for example, which would bring tremendous commercial value and help inform new fuel and ship design choices from the outset.

We can’t predict the future, but we can model it in a way that is grounded in data – and for the purpose of designing innovative ships, that’s already a sea of change.