NAPA Performance Model

The vessel performance models are built and improved using NAPA’s unique expertise accumulated during the 30 years of history as the leading provider of software, services, and data analysis for the maritime industry, providing best-in-class data-led solutions for safety, efficiency, and productivity in both ship design and operations.

For all vessels in the world, a ship-specific baseline performance model is built using the best knowledge about that particular vessel and the typical properties related to that vessel’s type and size. This model is already then perfectly usable for finding the best route alternative and for a rough estimation of the voyage costs.

If further accuracy is needed, the model is fine-tuned to the latest technical performance condition based on noon reports or automation signals available from any data source. This model fine-tuning based on new incoming data is continuous, creating a Dynamic Performance Model (DPM) that stays up to date.

Model creation starts from some basic knowledge about the ship, for example:

- ship type

- main dimensions

- deadweight / displacement

- installed main engine

- design draught and service speed

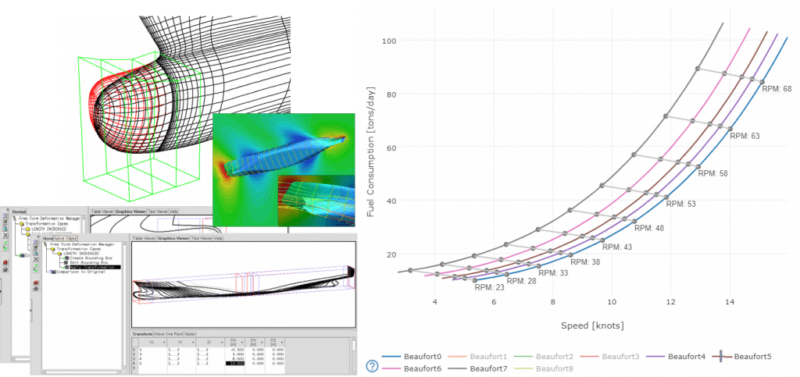

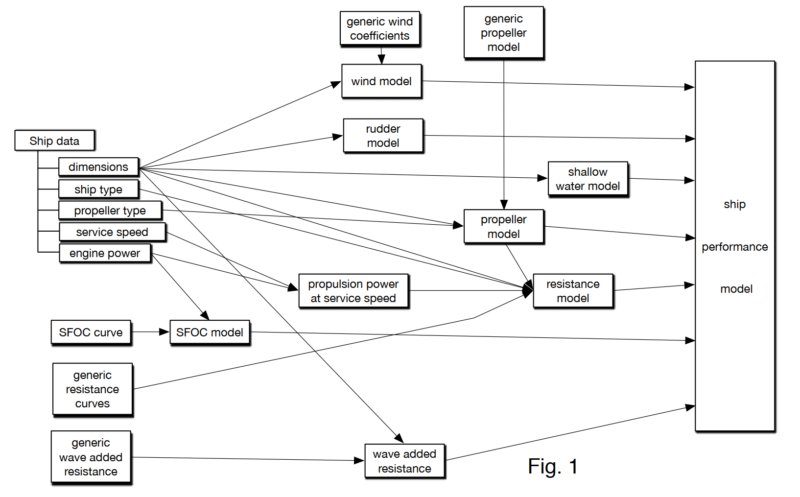

Using some simplifications, such as estimating propeller diameter based on ship type and main dimension, and using typical wind force coefficients instead of the ones for that particular vessel, several sub-models are created.

These sub-models take into account the vessel type, size, and typical properties of those vessels. A simplified illustration of the model creation process is shown in Figure 1. Since the image creation, several improvements have already been implemented to improve the model’s accuracy.

Model accuracy

The accuracy of the models have been verified by comparing simulated values based on the model and actual performance using either noon reports or performance data based on automation signals. This procedure has been carried out for hundreds of vessels from each vessel type. Initial model verification is done without any estimations on hull fouling. Therefore, the “error” includes the difference in prediction due to hull & propeller fouling, which in some cases can cause over 20% increase in fuel consumption.

The first level validation results in mean average percentage error are as below.

| Ship type | Mean Absolute Percentage Error (%) |

| Container ship, RPM | 4.9 |

| Container ship, energy | 5.2 |

| Tanker / bulker, RPM | 6.8 |

| Tanker / bulker, energy | 9.5 |

The error metrics are affected significantly by the vessels with poor technical performance, and typically the error is much smaller. The level of accuracy is sufficient for finding the optimum route and evaluating the relative cost difference between different routes and speed alternatives. For the vessels with the accuracy in the lower level, the RPM estimation might not be adequate for being used as a guide for voyage execution, but the speed is. Also, some offset in fuel consumption estimates can be expected in such cases, but it does not affect the usefulness of the optimization result in itself.

Model improvement with noon report data

If any reported data is available, the error due to technical performance differences can be reduced significantly within a few weeks. After this, the model is also usable for producing an accurate RPM profile of the voyage and for estimating the fuel consumption on a level that allows more use cases for the calculations and which gives the end users confidence that the results are reliable.

Model improvement with automation data

If signal data is available, the model can be tuned with a similar methodology as based on noon reports. In addition, it is possible to build a complete statistical model based on the underlying data. This is useful in specific studies or in revealing new relationships not available in traditional naval architectural models, such as verifying the effects of rotor sails or other fuel-saving devices.

Want to know more?

Book a demo

See the service in action, and ask specific questions in discussion with a NAPA expert.

Subscribe to NAPA Newsletters

Want to stay up to date on upcoming webinars, events, news, or product updates? Choose which topics you are interested in to receive relevant newsletters.

Read about

Questions?

Get more information

Fill in the form and we will be happy to respond to your questions and introduce our offering in more detail.

You can also be in touch with your local office directly.