March 23, 2021

NAPA brings unrivaled efficiency to novel ice-class vessel design process at Aker Arctic

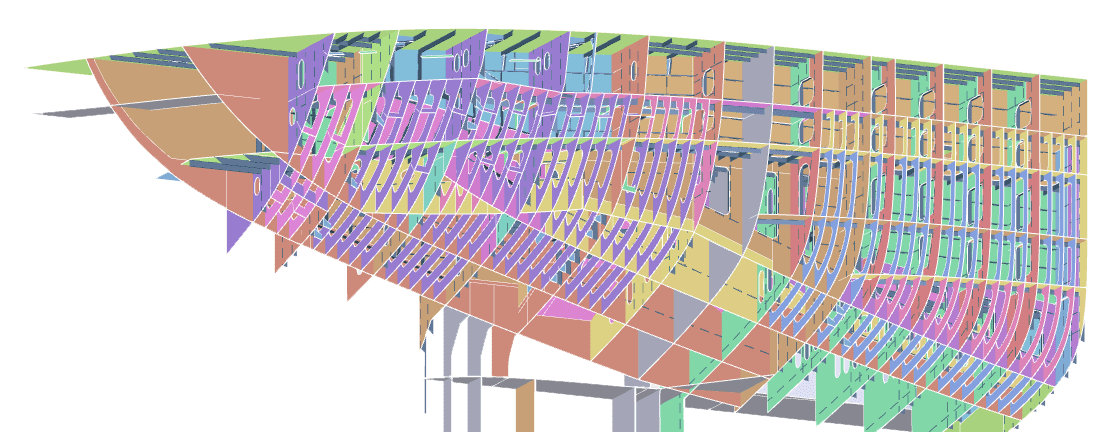

Aker Arctic uses NAPA FE meshing and NAPA Steel software to save time, increase flexibility and design capability on ice-class vessels concepts

Background

Aker Arctic is a leading Finnish engineering company specializing in developing the designs and related solutions for ice-breaking vessels operating in some of the world’s toughest conditions.

Aker Arctic has used NAPA software in its design processes for ice-going ships since its creation as a research facility at the Helsinki shipyard. Alongside weight and stability calculations, NAPA FE meshing enables complex analysis to be captured in one model across multiple software programs, reducing design errors, increasing accuracy, and saving valuable time.

Challenge

Aker Arctic is a market leader in the design of one of the most complex vessel types out at sea – the icebreaker. Unlike a typical cargo ship, which has a regular structure and is therefore easy to model, icebreakers feature more curvature in the internal and external structure, to ensure the vessel can move readily through the ice. Likewise, icebreakers require additional hull strengthening, which means they are structurally heavier than a traditional vessel. The unique design aspects of icebreakers make the design process incredibly intricate and time-consuming. Aker Arctic, therefore, requires intuitive 3D structural design software and a superior modeling interface to ensure its newbuild concepts, and ice-class upgrades, are seaworthy and meet strict class requirements. Likewise, with input from multiple engineers and design programs required, ensuring all changes are captured in one model while maintaining accuracy, and reducing errors, is paramount to Aker Arctic’s efficient design process.

NAPA Solution

NAPA is the industry leader in ship design software with sophisticated 3D modeling and design functionalities coupled with over thirty years of design expertise. Approximately 95% of the vessels in the global fleet are designed by NAPA customers. NAPA has therefore played a core role in helping enable Aker Arctic’s structural design process and the creation of its ice-class vessels.

“From using NAPA Designer throughout my studies at the Aalto University and daily in my current role, I have gained a huge appreciation for its adaptability, intuition and ease of operability. The sophistication of NAPA FE meshing has enabled us here at Aker Arctic to efficiently design and conduct complex numerical analysis to ensure vessels can operate safely in harsh ice conditions – NAPA is truly in a league of its own.” // Jillian Adams, Project Engineer, Aker Arctic

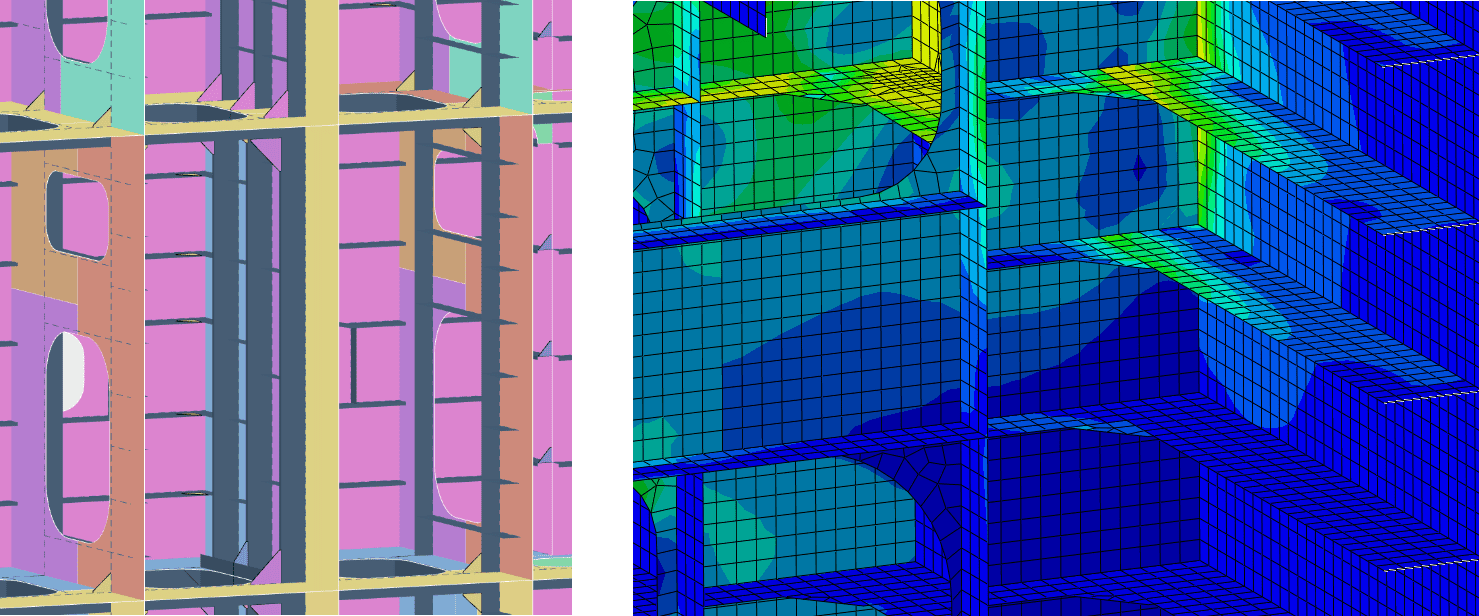

Aker Arctic has used the design functionalities available in NAPA Steel, with NAPA FE meshing, as the primary tool used to conduct time-efficient changes to highly intricate 3D models. NAPA allows for integration to other interfaces, which enables Aker Arctic to use the functionalities of multiple software while maintaining accuracy and applying changes to one model. The ability for multiple engineers to work on one model in multiple software, such as NAPA Steel and Abaqus, during the concept development and initial design stages, where changes to the design are rapid and significant, reduces errors. It also allows for a collaborative design process and reduces the drawn-out task of transferring data between programs. The clear and superior visuals within NAPA Designer also make the software easier to operate and intricate novel designs manageable for engineers spending long periods of time on one project.

Aker Arctic uses NAPA to run stability analysis and weight calculations on icebreakers. Alongside ship performance, stability, deadweight, and speed, NAPA Steel enables the company to model the intricate structures required to sustain high ice loads.

An example of Aker Arctic successfully applying NAPA FE analysis, was in a recent contract on a research vessel, in which Aker Arctic was tasked with conducting ice trials and estimating hull loads during different operational stages. The use of NAPA enabled Aker Arctic to take the 2D drawings and create detailed 3D models in NAPA Steel. Aker Arctic was then able to create very detailed meshing, which could then be easily exported to Abaqus, where a final analysis was conducted.

With a lot of existing FE software lacking the functionality to easily model complex icebreaker structures, NAPA having inbuild FE elements means you can create one ship model and conduct multiple analyses, which enables a smooth and integrated design process.

Conclusion

With NAPA Steel, Aker Arctic can save time and increase efficiency by further streamlining its design process by using a single consistent model throughout multiple design stages. Likewise, NAPA FE meshing is of value in such a specialized area, where models are not only incredibly unique in design, but required to deal with different structural pressures, such as ice loads. NAPA software has become an integral element in Aker Arctic’s design process, ensuring the company retains its position at the forefront of icebreaking technology.

Would you like to get more information about NAPA Steel?