February 5, 2021

A new dimension for ship design

by Tapio Hulkkonen, Director at NAPA Design Solutions

Moving automated ship design into the 21st century is a necessity that will require time and cooperation by all to achieve.

Ship design today

Ship design has long been three dimensional. And yet, despite this, for designs to meet class societies’ rules they still need to be translated into two dimensions. Then, once signed off by class, any feedback has to be re-translated back into three dimensions so that the ship designers can implement it. It’s a painfully inefficient and unnecessarily lengthy process.

A naval architect colleague and I recently estimated that a standard tanker hull structure will take approximately 3200 hours to design in 2D. Around 30% (or 960 hours of that time) is taken up with drawings, and about 65% (2080 hours) on calculations. For the design of a cruise ship, we concluded that it would be common for this process to take ten times longer.

Seeing clearly

Most naval architect studios today work from share documents, which means they’re always using the most current version. When you work from a single source of truth you save time, reduce risk, and can easily adapt to the changing needs to your clients. That’s yet to happen for ship design.

In 2019, more than 95% of shipyards that launched ocean-going newbuilds used NAPA design software for a least one part of their construction. From this vantage point we get to see enormous diversity of construction and use, and it opens up conversations with vessel designers about what they wish was possible. The vast majority recognize that these processes need to change, but as we also reluctantly conclude, this presents a chicken and egg situation.

Forward planning

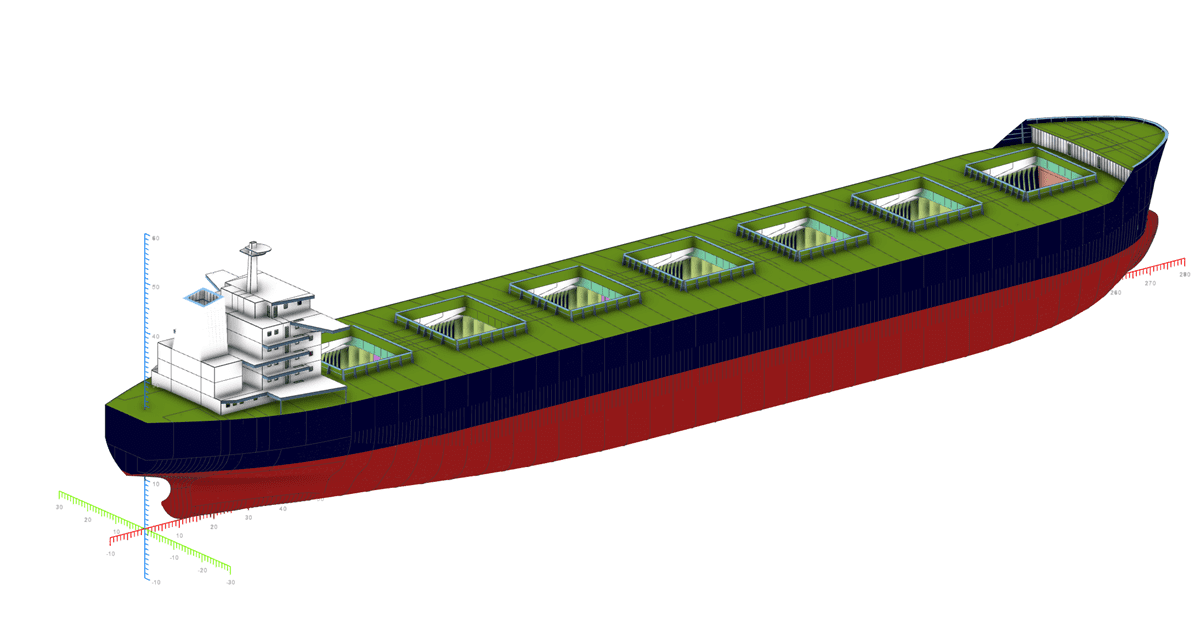

To help overcome this dilemma and to give us a better understanding of the practical realities, we’ve teamed up with ClassNK, the biggest classification society in terms of deadweight tonnage, and Japan Marine United (JMU), Japan’s second largest shipyard. Towards the end of 2019, we completed a joint feasibility study on 3D MBA (3D model based approval) using 3D CAD models. NAPA Designer, a 3D CAD software application for ship design, was used in the study to create a 3D model of a VLOC (very large ore carrier) by JMU.

At the end of the process, we reached two main conclusions. Firstly, that the same person can easily and effectively perform multiple rule checks and adjust designs without needing to learn multiple programs. And secondly, that all the information needed for class approval can be included in NAPA, the most commonly used ship design software.

You can read the complete article below (pages 40-41). It was originally published in Shipbuilding Industry (by Yellow & Finch Publishers) issue 5 in December 2020.