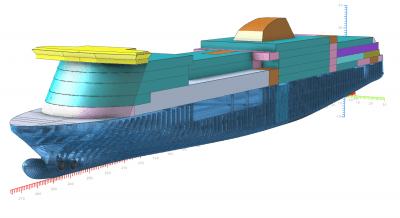

Structural Design

Efficient and easy 3D structural design for reliable weight calculation, class approval drawings and FE Meshing

Contact us Book a demoStreamlining structural design from concept to detail design

NAPA’s structural design solution, known as NAPA Steel, revolutionizes the entire process, starting from the project’s inception and continuing through to the detail design stage. By replacing traditional 2D drawings with our versatile NAPA 3D product model, the design process becomes more streamlined. Transitioning to the NAPA 3D model allows for earlier strength checks and more accurate weight estimations, promoting enhanced collaboration across various disciplines. The key benefits include optimized design, reduced lead times and project risk, and increased productivity in both ship design and production.

Benefits

Intuitive and efficient design with specialized 3D modeling tool

NAPA Designer offers a highly intuitive and efficient 3D modeling experience designed specifically for ship structural design. It facilitates rapid model creation through automation technologies and adaptable design changes, incorporating existing naval architectural models like hull form and compartments.

This tool ensures a versatile design experience tailored for ship designers, distinguishing it from other general CAD systems.

Streamline Finite Element (FE) analysis integrated with 3D design

Our cutting-edge auto-FE mesher, built on the same platform as 3D structural modeling, streamlines strength assessments. NAPA Designer’s tools automatically optimize the as-built 3D model into high-quality FE models for diverse analysis purposes, compatible with various external FE analysis software. With an integrated, early-available, and highly adaptable 3D structural model, achieving optimal, reliable, and cost-efficient designs becomes achievable.

Seamless integration with classification society rule check tools

NAPA’s structural design solution integrates seamlessly with major classification societies’ rule check software, including:

Bureau Veritas Mars, DNV Nauticus Hull, ABS Eagle UDM, ClassNK PrimeShip-Hull, Lloyd’s Register RulesCalc, Korean Register SeaTrust-HullScan and China Classification Society Compass SDP.

NAPA Designer supports the full specification of the Open Class 3D Exchange (OCX) standard, which is a testament to our commitment to industry collaboration and further innovation.

NAPA Drafting: Effortless drawing creation with best-in-class user interface

By leveraging AutoCAD technology, NAPA Drafting offers a best-in-class user interface for efficient drawing generation. It allows for easy extraction of 2D sections and the auto-add annotations from the NAPA 3D model in a short time. As the design progresses in its 3D form, NAPA Drafting consistently maintains and updates the 2D drawings, ensuring a seamless connection with the 3D model. This solution maximizes the benefits of 3D design in a workflow requiring 2D drawings for communication and approval.

Accurate numeric outputs from early design

Leverage NAPA’s 3D product model for accurate numeric outputs from the initial stages of design.

- Steel weight and center of gravity calculations

- Bill of materials for early material estimation

- Welding lengths and production cost estimation

- Painting area and coating estimation

- Insulation material estimation

- Optimal block division studies

- Any calculated data derived from 3D model

All outputs are auto-generated and customizable to suit your specific requirements.

Efficient collaboration via advanced 3D CAD interfaces

NAPA structural design solutions integrate seamlessly into the design process by interfacing with other software in the industry. Numerous general CAD formats are supported to import and export data from NAPA to support for example outfitting and to share information with the whole design organization. In addition, there are production design software-specific interfaces to:

- CADMATIC Hull & Outfitting

- Aveva Hull & Outfitting

- Hexagon Smart 3D

Equipped with NAPA’s 3D based tools, they rose to the occasion by working smartly, creatively, and collaboratively. Here’s how they achieved this masterstroke of speed and precision.

Read moreThe world’s largest shipyard, Hyundai Heavy Industries (HHI), implemented NAPA Steel’s 3D model-based ship structural design tool across its Basic Hull Design Department. This marked a paradigm shift for HHI – it facilitated a move away from 2D drawing-based process.

Read more

With NAPA 3D model and structural design solutions, KYMA streamlines yacht design and construction, reducing hull creation time from a year to two months and expediting system design and material procurement.

Watch moreBy integrating NAPA software into its initial design phase, Fosen Design and Solutions could easily take its models from 2D to 3D, laying the foundations for incomparable agility, fewer errors, and a smoother overall design process.

Read moreBy using NAPA design software for modeling, geometry, and to calculate stability, Samsung Heavy Industries’ (SHI) R&D center – Samsung Ship Model Basin (SSMB) – was able to design the Tri-Star Float model and enter the wind power generation market.

Read more

Elomatic’s use of NAPA’s 3D models and design software facilitates the exploration of alternative fuel options like LNG or ammonia, and the optimization of ship structures for safety, efficiency, and future fuel transitions, showcasing a commitment to green transition in maritime operations.

Read moreThe Technology Development Centre of Namura Shipbuilding, which oversees the development of concept design of standard vessels, uses NAPA when establishing an effective concurrent design process between the different disciplines.

Read more

Software

Questions or Demo?

Get in touch or Book a demo NAPA Steel

Please complete the form for answers to your questions and an in-depth introduction to our offerings.

To book a demo, simply check the demo reservation box in the form.

By submitting the form I consent my information to be used according to NAPA’s privacy policy